What Is The Investment Casting Process?

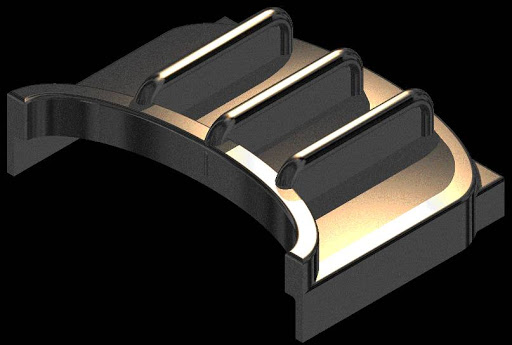

The Investment Casting Process is explained here. So learn the stages of the investment casting process in detail. What is the Investment Casting Process The type of casting process to be used for making a product depends upon its design requirements, cost, and feasibility. Here we are going to discuss the investment casting process . Investment casting is used to make small and intricate parts with high precision. This process saves a lot of energy and material waste. Thus, investment casting is widely preferred by engineers producing high-precision parts . What Is The Investment Casting Process? Investment casting involves the creation of wax patterns on a shell made of plastic or ceramic. The wax is melted away in a furnace. Molten metal is then poured into the shell to create the component as per the design of the wax patterns present on the shell. Stages of Investment Casting There are multiple stages in investment casting . Below is the explanation of the stages . Creati