What Is Casting Nickels Out Of Lead Meaning?

Nickel has the symbol Ni and Atomic Number 28 as a chemical element. It is a luscious silver and white metal with a faint golden tint. Nickel is hard and ductile to transition metals. Pure, powdery nickel displays high chemical activity to optimize the reactive surface. Although huge parts slowly react with air under typical circumstances because the surface is oxide-shaped and limits further corrosion (passivation). Nonetheless, in the earth's crust, pure nickel is found only in small quantities, mainly in extreme rocks and in the interiors of bigger nickel-iron meteorites that are not exposed to oxygen outside the atmosphere of the Earth.

|

| What is casting nickels out of lead meaning |

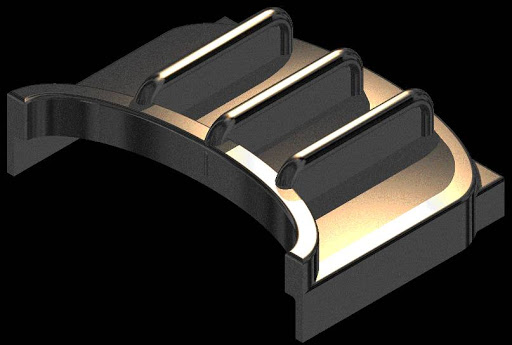

In keeping with the ever-changing client requirements, Nickel Alloy Casting manufacturers make and provide a broad variety of unique Nickel Casting applications which are utilized in industrial applications and are highly robust, corrosive, and high strength

Applications of Nickel Alloy

Worldwide nickel production is now utilized as follows: 68% in steel; 10% in nonferrous alloys; 9% in electroplating; 7% in alloy steel; 3% in foundries; and 4% in other applications (including batteries). Hydrogenation processes often include nickel and its alloys as catalysts.

The nickel industry and consumer goods, including stainless steel, alnico, coinage, rechargeable batteries, electronic guitar strings, microphone capsules, plumbing fixtures[66], and special alloys such as permalloys, elinvars, and invar, are well recognized. It is utilized as a glass plate and green tint. Nickel is mostly an alloy metal, and it is used mostly in nickel steels and nickel cast irons, in which tensile, toughness, and elastic limit are often increased. It is utilized extensively in many other alloys, including copper, chromium, aluminum, plumage, cobalt, silver and gold, nickel, and bronze alloys.

Also read: What Is The Investment Casting Process?

What does cast nickels out of the lead mean and do?

The choice of the alloy is a very essential component of the design of the component. The choice of the correct nickel-driven alloy depends on several parameters, including the environment to which nickel-driven castings are exposed during service. In addition, it's important to have a preliminary discussion with our metallurgist if the nickel-based alloy castings are to be used along with a wrought element (i.e. two components are welded together) to guarantee that you select the appropriate chemistry and material properties for your application.

Nickel-based casts are mainly employed for their exceptional heat-resistant and corrosive characteristics.

The names for cast stainless steel and nickel-based alloys in North America are indicative of their chemistry and use. A classification starting with the letter "C" denotes that the alloy is mostly utilized for corrosive duty. When the first letter is "H," the alloy is often utilized to serve at or above 1200°F high temperature.

Monel, Inconel, and Hastelloy are common high-nickel alloys:

- For a set of nickel base casting and nickel alloys made predominantly of nickel and copper with tiny quantities of iron, manganese, carbon, and silicone, Monel is the common denominator. Monel alloys are stronger than pure nickel and resist corrosion by numerous causes, including fast-moving saltwater. Compared to steel, Monel is exceedingly hard to manufacture since it works incredibly fast. It must be rotated and operated at low feed rates and modest speeds.

- Inconel is a family of austenitic chrome-based superalloys, also referred to as "Inco." Inconel alloys are oxidation and corrosion-resistant and are well suited for service in extreme environments subjected to pressure and heat. Inconel generates a thick, persistent, passive oxide layer when heated that protects the surface from further assault. Inconel keeps strength over a broad variety of temperatures and attracts applications with high temperatures where aluminum and steel would subside due to thermal crystal vacancies. The high-temperature strength of Inconel is generated by reinforcing the solid solution or hardening precipitation depending on the alloy.

- The primary function of the Hastelloy super alloys is that of effective survival under high-temperature, high-stress service in a moderately to severely corrosive, and/or erosion-prone environment where more common and less expensive iron-based alloys would fail, including the pressure vessels, chemical reactors, distillation equipment, and pipes and valves in the chemical industry.

Nickel Alloy Casting Manufacturer offers Nickel Alloys Casting, which is widely used in a variety of sectors. These castings are highly recognized for their outstanding tolerance and are commonly utilized in corrosive and high-temperature applications. The Nickel Alloys Casting is offered at the best pricing on the market.

Comments

Post a Comment