Can Inconel Be Cast?

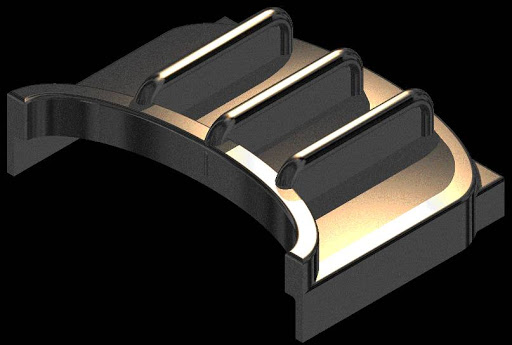

Inconel investment castings

Inconel investment castings are made by vacuum induction melting (VIM) bar stock, followed by hot isostatic pressing (HIP), and then subjected to an age-hardening process. Inconel alloys have outstanding welding qualities, making them ideal for repairing casting faults or making repairs in-service. Inconel is a trademarked brand of Special Metals Corporation that refers to a broad product range of superalloys manufactured from nickel, chromium, and austenite. Inconel alloys are often used in high-temperature applications, such as furnaces. They are referred to as Inconel or Inconel alloys in English, depending on the context.

|

| Can Inconel Be Cast? |

Because of the quick work hardening that occurs with Inconel, it is difficult to form and machine. Work hardening plastically deforms either the tool or the workpiece on subsequent machining operations after it has been subjected to the initial machining operation. As a consequence, age-hardened Inconel are machined with a hard tool to get the desired outcome. The use of this kind of tool removes the need for the Inconel to go through several different procedures.

On the other hand, the majority of the machining may be done after the material has been age-hardened. The exterior threads are machined on a lathe or rolled on a screw machine to provide the desired appearance. The holes with external threads are created by brazing or welding stainless steel threaded inserts into the holes with external threads. A water jet cutter is often used to cut through plate material. Thread Milling may also be used to cut internal threads, which is advantageous. Inconel alloys are machined with the use of ceramic cutters as well. These tools are more efficient in removing material than carbide cutters.

Welding Inconel alloys is a difficult process due to the microstructural segregation and breaking of alloying components in the heat-affected region caused by the high temperatures. Although certain alloys have been specifically engineered to overcome this issue, others have not. The gas tungsten arc welding process is the most often utilized welding process. In addition, novel technologies for joining alloys, such as pulsed micro laser welding, were employed to accomplish this.

Inconel Casting Manufacture makes a variety of applications such as nuclear power plants, satellite launch programs, power production, maritime and mining and exploration, and related fields of use. Furthermore, the high strength, outstanding tolerance, durability, dimensional precision, rust-resistant nature, and abrasion resistance of the supplied range have earned its widespread acceptance among customers.

Is It Possible To Cast Inconel?

Inconel alloys have outstanding welding qualities, making them ideal for repairing casting faults or making repairs in-service. The high-temperature strength of Inconel is achieved by either solid solution strengthening or precipitation strengthening, depending on the alloy. At temperatures as high as 1700°F (927°C), Inconel 713C Castings exhibit great resistance to thermal fatigue and remarkable rupture strength.

Machining and shaping are two terms that are used to describe the process of creating anything from scratch. Inconel investment castings are made by vacuum induction melting (VIM) bar stock, followed by hot isostatic pressing (HIP), and then subjected to an age-hardening process. Inconel alloys have outstanding welding qualities, making them ideal for repairing casting faults or making repairs in-service.

Also read: What Is The Investment Casting Process?

Uses of Inconel Casting

When working at a high temperature, Inconel metals are often employed in a variety of applications. Gas seals, rotor blades, and combustors, as well as turbocharger sealants and blades, elevated temperatures fastening, motor shafts, temperature and chemical processing containers, coolant pumps, heat transfer tubes, and catalytic converters, are among the most common applications. Waste incinerators, among other places, make use of these alloys in their boilers.

Inconel Casting Manufacture is a professionally managed investment casting foundry that is committed to providing Consistently High Quality. They are dependable when it comes to providing a diverse range of General Inconel Casting Parts. They are capable of producing in huge, medium, and tiny quantities. They have built a solid reputation by supplying castings to a diverse variety of sectors by their standard requirements as well as in bespoke sizes and a broad variety of materials options. It is the goal of their skilled personnel to provide a greater product value, rather than merely a reduced unit cost with the guaranteed quality delivered on time.

Comments

Post a Comment